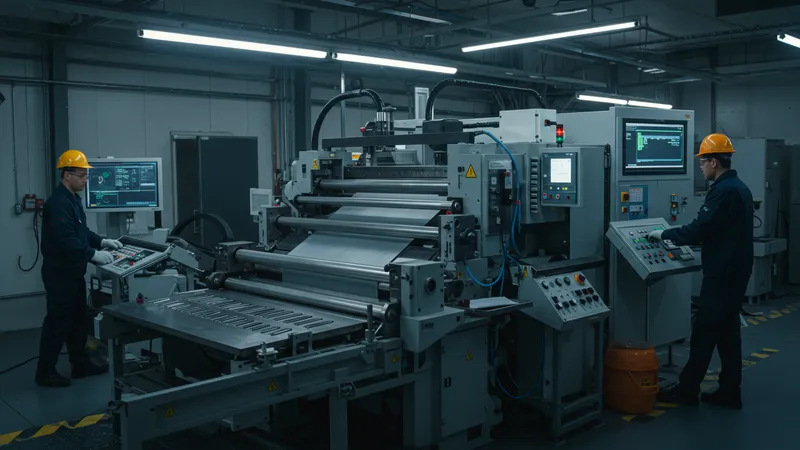

The world of manufacturing just took a mind-blowing turn. The latest slitting machines promise precision and speed like never before, leaving industry experts speechless at their capabilities.

In today's fast-paced market, maximizing efficiency is critical. Advanced slitting machines are redefining production, but can they really live up to the hype?

Forget what you think you know about slitting machines. The new age of slitting technology not only boosts efficiency but also significantly cuts energy consumption. Recent models, such as the SLITMAX Pro 2000, have demonstrated the ability to manage high-volume operations while consuming 40% less power compared to older models. But that’s not even the wildest part...

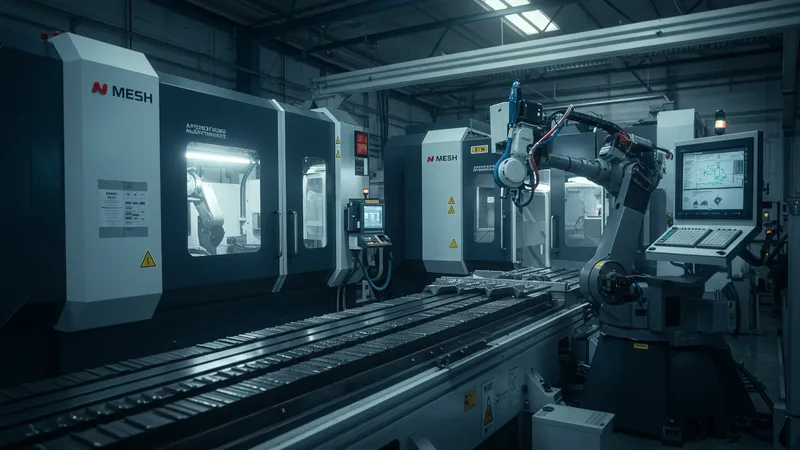

EdgeTricker X5 has stunned analysts with its automated precision capabilities. Operating with laser-guided cutting technology, this machine can handle the most delicate materials without the slightest error. Perfect cuts every time, it’s revolutionizing how manufacturers think about precision. But there’s another game-changing feature you won’t believe...

The next evolution in slitting technology shocked even the experts when they realized the potential impact on global manufacturing practices. Could this be the turning point for industrial efficiency, or just another technological fad? What happens next shocked even the experts...

While most people look at slitting machines solely for their cutting efficiency, the real surprise lies in their secondary benefits. The latest machines are surprisingly eco-friendly. They produce less waste material and require less energy, which is a big win for companies aiming for sustainability. Furthermore, some manufacturers reported up to a 30% reduction in material waste when using updated models, which cuts costs and benefits the environment. These facts might make you rethink what high-tech machinery can do in sustainable practices.

But there’s more – the integration of AI into these machines is subtly changing the workforce dynamics. With smart sensors and self-diagnostic capabilities, these machines reduce the need for constant human supervision. It’s not about replacing jobs but transforming them into roles that require critical thinking and problem-solving, drastically increasing employee engagement and morale. But there is still something unexpected about how these machines adapt to dynamic production needs.

The cherry on top? Customer feedback loops in the design process have allowed manufacturers to innovate based on real-world use and needs. Machines like the SLITMAX Pro 2000 have rapidly evolved, addressing issues that users never thought would be considered. These adaptive machines are not just tools; they are partners in the production line journey. This upgradeable nature might just redefine ‘investment’ in the industrial sector.

The influence of these machines on the supply chain is yet another surprise. As supply chains become more streamlined, it’s fascinating to see how such technological advances can eliminate inefficiencies that currently plague industrial operations. But there’s another hidden benefit that could reshape global logistics as we know it. What comes next? Might just rewrite the logistical playbook entirely.

The competition among manufacturers is fiercer than ever, and every company is searching for that edge to stay ahead. Enter the modern-day slitting machine, designed not only for precision but also enhancing productivity in ways previously unimagined. The introduction of faster cutting speeds means output rates can exceed previous models by 50% or more. This ramping up of the production line directly translates to higher profits with less downtime.

Take, for instance, the EdgeTricker X5; its capacity to perform more complex tasks without human intervention means more can be accomplished with less. It’s the dream tool for any company looking to maximize labor efficiency while minimizing the risk of errors. But, the unexpected revelation is how this impacts project timelines.

Furthermore, it isn’t just about speed; reliability plays a crucial role. The latest machines boast enhanced durability, designed for longer operational hours without the need for regular maintenance spells that stall productivity. Companies embracing this tech are seeing increased uptime alongside reduced operational costs, making these machines essential in an era of tight profit margins.

Yet, the most thrilling aspect is how these machines incorporate modular designs, allowing for easy upgrades when new technology or cutting techniques are developed. By future-proofing operations today, manufacturers are setting themselves up for long-term stability. So, what lies ahead in this technology’s journey? You won't believe the upcoming innovations.

The continuous evolution of slitting machines goes beyond mere technical specs—they’re becoming more intuitive, thanks to advanced AI and machine learning algorithms. Imagine a machine that not only cuts but learns your processes and adjusts them in real-time to enhance efficiency. This smart slitting could be the ultimate competitive advantage.

Take, for instance, how newer models now come equipped with self-regulatory functions that allow them to calibrate themselves for optimal performance during each session. Operators have reported significant time savings, attributing this feature to increased net output over time. Yet, the real marvel lies in what this could mean for innovation in other sectors.

The impact isn’t just confined to individual companies. Industry-wide, these technologies are paving the way for collaborative innovations, with shared insights contributing to better practices across sectors. Collaborative platforms are arising where industry players share data-driven insights, improving operational strategies globally. A smarter, interconnected industry might just be around the corner.

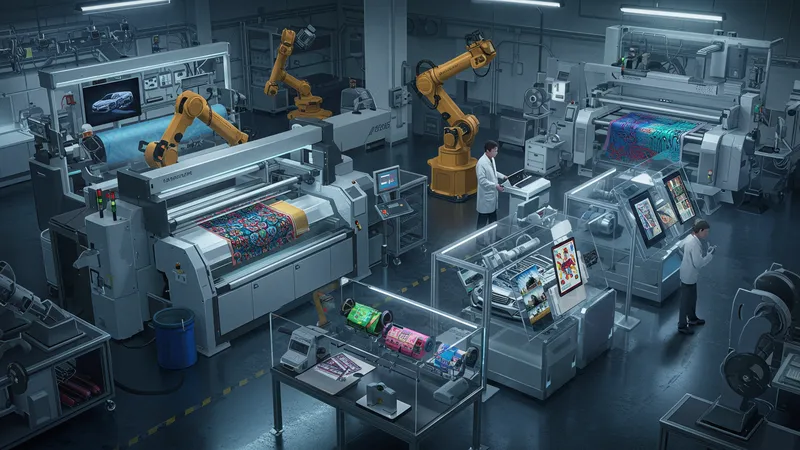

Moreover, the influence of slitting machines stretches beyond customary industrial lines. The potential applications of their refined technology are broadening, venturing into unexpected areas such as art installations and intricate designs that were previously deemed impossible. The potential for creativity unleashed by accurate cutting tools is making headlines, and the extraordinary outcomes might soon be as commonplace in art galleries as in factories. But, of course, there’s an even more unpredictable front they are set to transform.

Initially, modern slitting machines were imagined strictly within the rigid confines of industrial usability, yet they now find applications that extend far beyond original expectations. The architectural world is yet another arena transformed by these machines. Precision cutting is being used in creating bespoke structures that require minute accuracy and intricate detailing, resulting in stunning architectural statements.

Not to be left out, the textile industry is also witnessing a facelift. With the ability to precisely cut thin and varied materials, the fashion industry can experiment with innovative designs that push the boundaries of conventional couture. The EdgeTricker X5 has already been celebrated for revolutionizing the way delicate fabrics are handled, securing its place as an invaluable tool in high fashion houses.

And let's talk about prototyping. Engineers across different fields are finding slitting machines indispensable, allowing them to make accurate models and designs quickly, facilitating faster innovation cycles. The versatile nature of these machines allows for groundbreaking developments in product design and experimentation.

But this is just the beginning. With advancements in material technology, there’s a burgeoning possibility for slitting machines to take on unconventional materials, opening a new realm of practical applications that could dramatically reshape global manufacturing industries. The potential expansion of these capabilities is worth keeping an eye on—especially because the next big leap might be closer than anyone could have ever predicted.

While the benefits of modern slitting machines are clear, one cannot ignore the unforeseen costs they bring. The initial investment, although hefty, is not the only financial consideration. The demand for specialized maintenance and training is an ongoing expense that companies need to plan for appropriately to protect their investment.

There’s also the issue of technological obsolescence. With rapid advancements, today's top-tier model might become outdated in a matter of years, prompting regular updates or replacements. This accelerated pace of technology demands savvy strategic planning to stay ahead without bursting budgets.

Yet manufacturers have found innovative solutions to this dilemma through leasing models and partnerships with machine suppliers. These approaches help manage costs while granting access to the latest technology—an ideal solution for smaller companies with limited resources. But what’s truly surprising is the alternative funding and grant programs supporting tech adoption.

Government incentives for upgrading resources to energy-efficient technologies are increasingly more available. Companies leveraging these benefits can offset the high costs associated with state-of-the-art machinery. It turns out, aligning tech upgrades with green initiatives is not only financially savvy—it’s a strategic move ensuring companies remain competitive in an escalating market. Yet even with these solutions, what the future holds for investment costs remains under speculation.

Today’s wise investments in slitting machines could be tomorrow’s strategic advantage, yet the foresight for future-proofing operations to remain relevant is vital. Regular tech updates, scheduled maintenance, and timely upgrades offer a way to navigate technology’s shifting landscape seamlessly.

Programming and software development tailored to specific operation needs are becoming increasingly crucial. Customizations ensure that the slitting machines remain aligned with evolving process complexities, allowing organizations to maintain cutting-edge capabilities without the redundancy of ongoing machine changes.

Moreover, training programs geared towards up-skilling employees in utilizing new technologies bring dual benefits: operational competence and employee retention. Companies investing in human resources simultaneously sharpen their technical edge, ensuring long-term stability in both workforce competence and output quality.

However, truly future-proofing in today’s manufacturing means preparing for diversified uses across different sectors. Recognizing crossover potential can spell the difference between stagnation and pioneering in new markets. So, what could this entail for an industry standing on the brink of cross-disciplinary innovation?

As industries across the globe continue to evolve, the role of slitting machines has seen fascinating developments beyond the factory floors. Global market trends highlight a marked shift in priorities towards sustainability, adaptability, and globalization, all areas where slitting machines are surprisingly creating waves.

There is an increasing trend for machines that can switch functions seamlessly, responding to varied global demands. This adaptability isn’t just a luxury; it's becoming a necessity in a world where manufacturers cater to diverse and rapidly changing needs.

Additionally, as companies push towards net-zero targets, slitting machines serve as pivotal elements in reducing carbon footprints. By minimizing waste and optimizing resource use, they complement global goals, reinforcing environmental commitments while ensuring productivity.

As international markets converge, the ability for slitting services to cater to different regulatory standards is becoming paramount. Alignment with global manufacturing practices is more critical than ever, as slitting services grow into roles that support international trade and collaboration. The implications of these trends cannot be understated; they signal a future where slitting machines are vital cogs in the wheels of global commerce.

Artificial Intelligence and robotics have long been touted as the future of industrial operations, and their infusion into slitting technology demonstrates this potential vividly. The convergence of AI with precision cutting tools has produced machines of unparalleled capability and efficiency.

By harnessing AI, today’s machines can predict potential wear and tear, schedule maintenance autonomously, and optimize cutting paths in real-time—cutting down waste and maximizing output efficiency. This not only boosts productivity but also extends the lifespan of machines, contributing to cost-effectiveness.

Robotics further enhances the value proposition by enabling delicate operations and handling materials that require extreme precision with minimal error margins. These advancements make them indispensable in top-tier industries requiring flawless outputs such as aerospace and microelectronics.

The ripple effects of this technological integration are profound, with machine-learning capabilities supporting new achievements in customization, modular upgrades, and system collaborations across varying production lines. The future, intertwined with AI and robotics, promises to redefine what we consider possible in precision manufacturing. The exploration continues on how this technology could be replicated in other industrial processes.

A surprising beneficiary of advanced slitting machine technology is the DIY space. No longer confined to professional factories, these machines are entering consumer spaces, transforming homes and small businesses with unprecedented cutting precision.

DIY enthusiasts now have access to compact versions of these machines, fitting in workshops and allowing users to tackle intricate designs that once required industrial prowess. This democratization of technology is fostering innovation at the grassroots level.

Small businesses and entrepreneurs are leveraging these compact machines to produce custom goods swiftly and efficiently, from bespoke furniture to unique fashion accessories. This capability is encouraging a wave of creativity and entrepreneurship that further blurs the line between professional and amateur production capabilities.

The DIY movement, bolstered by such tools, is part of a broader trend of individualized market offerings that promote localized production, reducing transportation costs, and allowing for personal customization. The potential of what slitting machines can catalyze in this space is only just beginning, and it's reshaping industries from the ground-up.

Industries constantly shift as new materials emerge, requiring precise and adaptable cutting techniques. Modern slitting machines are rising to meet these challenges head-on by accommodating an ever-expanding array of inventive materials.

From advanced composites used in aerospace to groundbreaking biodegradable materials in packing solutions, slitting machines offer the versatility needed to handle these with the utmost precision. This adaptability ensures businesses can meet evolving customer expectations with the latest material innovations.

Furthermore, as eco-friendly materials become the industry standard, slitting machines' role in ensuring precise and waste-efficient cutting grows even more critical. They reduce material wastage, providing an economic and ecological boon for companies striving to meet sustainability commitments.

The key lies in their unprecedented ability to adapt to material-specific demands, offering solutions that surpass traditional cutting methods. As this technology continues to evolve, it opens new doors, including the potential for handling even the most delicate of materials in sectors previously unimagined.

Interestingly, the relationship between low-tech processes and high-tech advancements creates opportunities for innovative manufacturing methodologies. Slitting machines combine traditional manufacturing spirit with cutting-edge technology, creating a complete package that harmonizes the best of both worlds.

This fusion allows for the incorporation of artisanal methods into high-output production processes. By embracing both old and new, manufacturers can enhance quality while maintaining the artisanal essence sometimes lost in industrial scaling.

The seamless transition between these techniques ensures consistency in outputs with improved efficiency, striking the perfect balance between technology and craftsmanship. It’s a revolutionary shift that respects tradition while pushing the boundaries of what manufacturing in the modern age looks like.

The ability to blend low-tech traditions with state-of-the-art innovations is shaping a new manufacturing identity, one that empowers industries to reinvent themselves in unprecedented ways. As these avenues develop, they will redefine how simplicity meets ingenuity, inspiring new industrial models that thrive on this unique synergy.

Amid the bustling innovation within the realm of slitting machinery, many are astounded by the significant strides towards eco-friendliness. It’s an unexpected development that aligns perfectly with today’s sustainability imperatives.

Modern slitting machines have evolved to become integral in producing materials previously seen as impossible with traditional machinery. They are key players in creating bioplastics cut with unmatched precision, greatly benefiting packaging industries striving to replace plastics with biodegradable alternatives.

Moreover, their efficiency in managing energy consumption is noteworthy. With designs focused on optimizing power usage, they contribute to overall reductions in industrial emissions, marking a commendable step toward net-zero carbon goals.

This shift signifies more than just environmental consciousness; it defines a critical business strategy moving into the future. Emphasizing eco-conscious production becomes a cornerstone of modern manufacturing, promising the next stage in industrial evolution—one where green meets profitability in previously unimaginable ways.

Customization is the buzzword of the future, with slitting machines leading the charge in redefining what bespoke means in modern manufacturing. The ability to personalize products with unparalleled precision satisfies a growing consumer demand for tailored solutions.

This represents a groundbreaking shift in textile, automotive, and consumer electronics industries, among others, where personalization has become a unique selling proposition. Companies understand that customer satisfaction hinges on not just quality, but also on delivering personalized experiences.

Slitting machines, with their adaptive tech, have the potential to transform identities for businesses vying to set benchmarks in customization, enhancing their competitive stance within increasingly crowded markets.

Perhaps the most intriguing aspect lies in anticipating consumer trends, where machines can evolve in anticipation, rather than as a reaction. This proactive customization ability is setting new standards, making way for a future where production doesn’t just meet demands, it anticipates and shapes them.

In the end, the journey of the modern slitting machine is a tale of technological evolution that even experts are struggling to fully grasp. As new innovations emerge, one question remains tantalizingly open: How far can these precision tools push the boundaries of manufacturing in every imaginable sector? This story is far from over and writing its next chapter could be a journey that affects industries, economies, and societies for years to come. Share this story, save it for later, or even better, take a step forward into the future of precision manufacturing by understanding its potential impacts today.